Know more about

Fundição Moreno

The foundry sector currently occupies a total area of 140,000 m², with 26,500 m² of built area. Divided into two sub-sectors, the company has a specialized manufacturing plant for the production of large parts, and another one, established in 2004, which produces small and medium-sized parts.

The current installed capacity is 20,000 t/year of finished cast parts. For this, Moreno has modern induction furnaces with different powers and capabilities to produce parts from 50 kg up to 30,000 kg of final weight, plus a wide range of casting ladles to comply with all the pieces portfolio.

The molding process is manual and is splitted into four cells. It uses the cold-curing system with two sand mixers (mobile and fixed), with capacity of up to 60 t/h, and with molding boxes of up to 4.5 x 4.5 m. At the end of this process, 90% of the used sand is reclaimed.

Furthermore, Moreno has five modern heat treatment furnaces with a capacity of 3.5 x 2.5 x 2.0m to 5.0 x 8.0 x 3.0 m, with the best gas burners technology, thereby ensuring the homogeneity of the temperature, which is regulated by control points and graphical records.

The Company carries out internally treatments of standardization, solubilization, tempering, stress relieving and water hardening. The finishing area has manual and automatic sandblasting equipment, complete and integrated cells for deburring, welding and inspection, with a qualified team of welders and inspectors. All units are well equipped with overhead cranes of various capacities, ranging from 10 up to 60 tons.

Within this concept, Fundição Moreno has been investing in manufacturing structure and equipment, such as Magma software for casting process simulation, a Romi 3D arm and Laser Tracker for model and cast parts inspection, a new 25 tons pan, a Panasonic welding robot for mill shells and a new heat treatment tank for large parts.

In addition, the board of Fundição Moreno, with great pleasure, aiming at always provide excellence to our customers, reports the opening of a branch in the South region of Brazil, where we will have a new structure focused at the sugar-energy market.

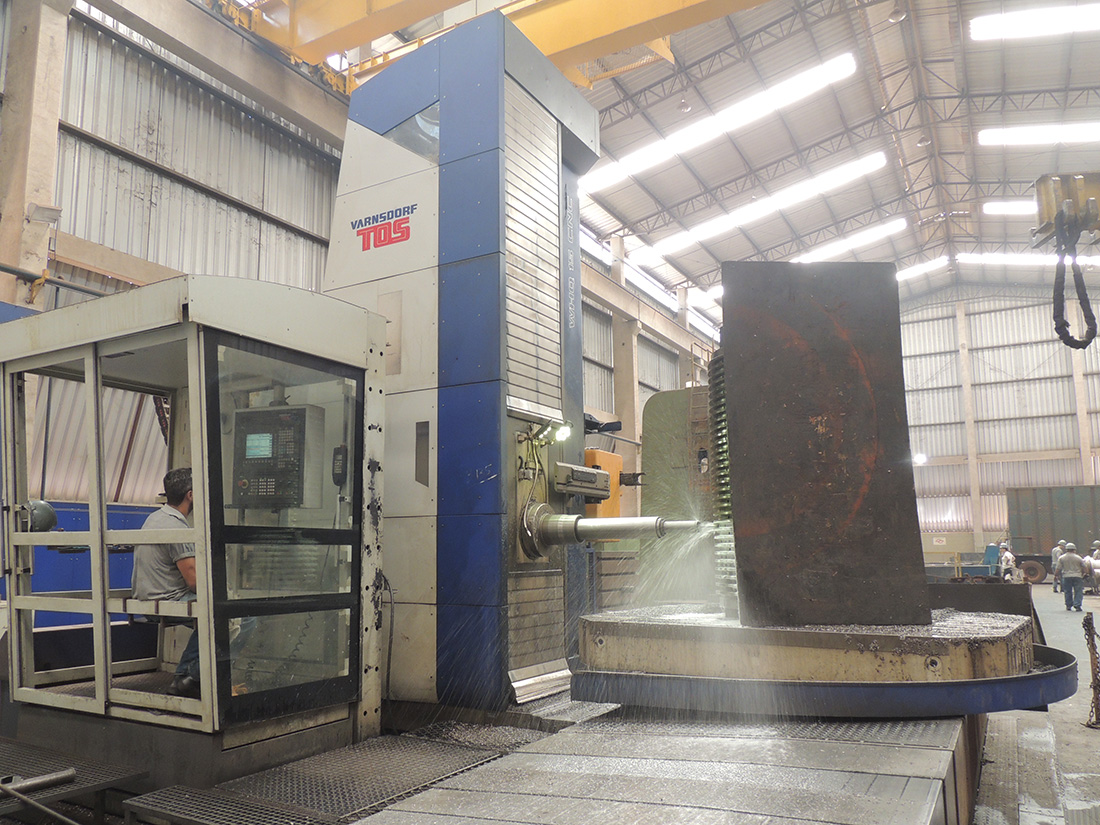

Machining

The machining park has heavy and precision machinery, as well as conventional and CNC ones, offering thinned or complete machining parts, and may also include welding and assembly services.

The company has two machining units, with a total built area of 7,000 m². It has a full range of tools, gauges and devices for measuring and controls, in addition to a trained team of operators and inspectors. Just as the foundry, also Moreno´s machining also has ISO 9001 certification. Moreno is fully adequate to comply with the most diverse market segments, with the strictest levels of tolerance and finishing.